Central Steel Supply Company stocks expanded metal in raised, flattened, and expanded grating designs. These products deliver durable steel performance with uniform diamond patterns suited for protective panels, equipment guards, platforms, screens, decorative elements, and general‑purpose fabrication work. This overview highlights the available material types, their characteristics, and the ways Central Steel Supply Company supports efficient project planning and material coordination.

The following sections outline material types, dimensional characteristics, and the value-added advantages Central Steel Supply Company provides through coordinated material support and reliable product availability.

Types of Expanded Metal

Raised Expanded Metal

Raised expanded metal is produced by simultaneously slitting and stretching steel sheet, forming an interconnected diamond-shaped pattern. The resulting design offers increased rigidity, slip resistance, and multidirectional strength. The strands and bonds remain integral to the sheet, creating a single-piece product with no welds.

Characteristics include:

- Efficient strength-to-weight performance due to the work‑hardened strand profile.

- Enhanced traction resulting from the raised diamond pattern.

- Open area suitable for airflow, drainage, or screening where structural capacity is still required.

Flattened Expanded Metal

Flattened expanded metal is produced by cold‑rolling raised expanded metal after the initial expansion process. This compresses the diamond profile to create a smooth, uniform sheet with reduced overall thickness and a flatter surface.

Characteristics include:

- Smoother material surface beneficial for applications involving attachment, enclosure, or handling.

- Reduced profile height while retaining the integral diamond pattern and consistent open area.

- Suitable for walkways, guards, partitions, and general screening where a less prominent pattern is preferred.

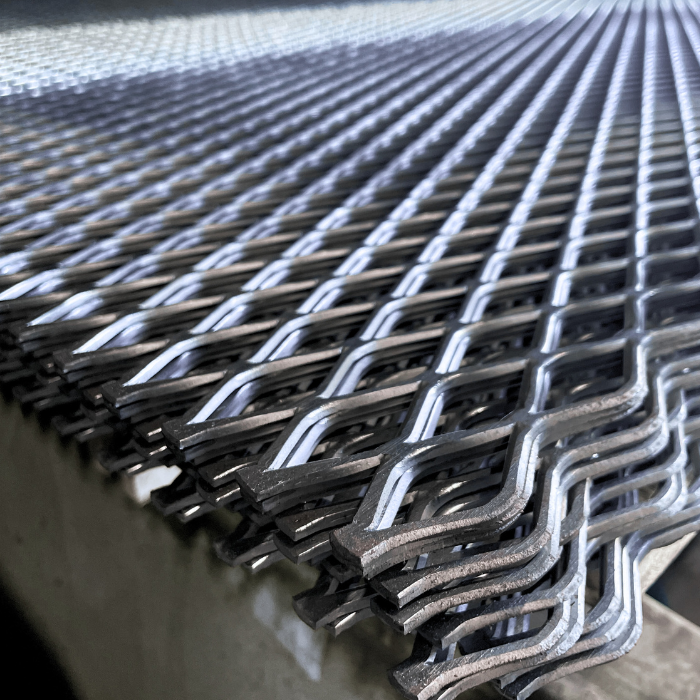

Expanded Grating

Expanded grating is a heavy-duty form of raised expanded metal produced from thicker steel plate. Although commonly referred to as “grating,” it differs from welded bar grating because it is not made from individual bars; instead, it is a single-piece product created when plate is slit and stretched to form large, heavy diamond openings. The process produces wide steel strands that result in a stronger, more rigid, and heavier sheet than standard expanded metal.

Characteristics include:

- High load-bearing capacity suitable for industrial platforms, equipment access areas, and rugged service conditions.

- The same diamond-pattern concept as standard raised expanded metal, scaled to a heavier design.

- Increased rigidity and traction due to the wider, heavier strand profile.

This single-piece construction delivers durability and performance similar to bar grating while eliminating welded joints, making it well-suited for demanding environments.

Dimensions, Grades, and Value-Added Support

Central Steel Supply Company stocks expanded metal in 48″ × 96″ sheets, with additional sizes available through trusted partner sources.

Flattened & Raised Expanded Metal is commonly identified in terms of:

- Diamond short way of design (SWD): distance across the narrow width of each diamond. Or in other words, SWD is the short width dimension (SWD) of each diamond opening, measured from the center of one bond to the center of the adjacent bond.

- Material Thickness: Also referred to as the “strand” thickness, this is the thickness of the original sheet before expansion.

Example: Raised Expanded Metal ¾” x 9 ga – The 3/4″ dimension is the SWD, and the 9 ga is the thickness of the material expressed as a gauge as opposed to inches. In this example, 9 gauge is equivalent to 0.149”.

However, there are further identifying dimensional properties associated with this material, but are not necessary to provide when ordering material. These dimensions are:

- Diamond long way of design (LWD): the distance across the longer dimension.

- Strand width: the amount of steel left between each diamond opening.

- A larger strand width increases the sheet’s rigidity, enhances its ability to resist bending, and improves durability in applications where impact, vibration, or repeated loading are present. It also influences the sheet’s overall weight, edge strength, and suitability for forming or welding.

Expanded Grating (heavy-duty expanded metal) is commonly identified in terms of:

- Strand width: The dimension of the steel strand separating each diamond. Heavy expanded grating uses numeric designations—#4, #7, #9—to indicate strand width in sixteenths of an inch (e.g., #4 = 4/16″ = 1/4″). This measurement defines the strand’s width, not the material thickness used to produce the sheet.

Example: #4 Expanded Grating — The #4 designates the strand width, measured as 4/16″ (which simplifies to 1/4″). This refers to the strand width, not the thickness of the material.”

Typical Grades of Expanded Metal

Expanded metal is most often produced from low-carbon sheet or plate because it forms and stretches well during the slit-and-stretch process.

Typical grades include:

- ASTM A36 — common for heavier expanded grating (plate-based)

- A1011 CS (Commercial Steel) — standard for light/medium expanded metal

- A1018 — used for heavier-gauge or structural-quality expanded metal

NOTE: Stainless steel and Aluminum Expanded Metal options can be coordinated through trusted partner sources, allowing Central Steel Supply Company to support one-stop material procurement for customers requiring alternative alloys.

Although expanded metal is supplied without cutting, shearing, or forming, Central Steel Supply Company supports customers through dependable inventory, coordinated procurement of complementary materials, and assistance in selecting profiles suitable for the intended structural or architectural purpose.

Value-Added Support

Although expanded metal is supplied without cutting, shearing, or forming, Central Steel Supply Company strengthens project efficiency through dependable inventory, coordinated sourcing of complementary materials, and guidance in identifying profiles appropriate for the intended structural or architectural purpose. This coordinated approach forms the foundation of the value-added support Central Steel Supply Company provides.

Central Steel Supply Company stocks raised expanded metal, flattened expanded metal, and #4 expanded grating in standard 48″ × 96″ sheets. These materials provide consistent, reliable performance suited for forming, welding, or integration into fabricated assemblies. Practical product knowledge, reliable availability, and streamlined procurement help fabricators and contractors keep labor focused where it provides the greatest value—both in the shop and on the jobsite.

Even without processing services, expanded metal supplied in consistent 48″ × 96″ sheets offers practical advantages:

- Predictable handling and staging for fabricators seeking reliable stock materials.

- Straightforward integration into shop workflows without managing variable sheet formats.

- Uniform profiles that support efficient layout planning, material nesting, and productive use of shop resources.

Central Steel Supply Company further enhances project coordination by:

- Offering material-selection insight aligned with general structural intent without providing engineered load recommendations.

- Coordinating complementary items such as structural shapes, plate, or reinforcement products to simplify procurement.

- Supplying consistent, ready-to-use material so fabricators can maximize labor efficiency on fabrication, assembly, and jobsite deliverables.

Industries and Common Applications

Expanded metal and expanded grating support a wide range of applications across multiple industries.

- Commercial Construction and Engineering: Walkways, equipment guards, mechanical room platforms, screening panels, and flooring surfaces requiring slip resistance.

- Industrial: Machine guarding, heavy‑duty platforms, ventilation panels, access landings, and protective barriers.

- Residential Construction: Security screens, enclosure panels, ventilation covers, and general utility applications.

- Municipal & Infrastructure: Utility enclosures, equipment housings, pump room guards, and facilities requiring durable, open‑area panels.

- Fabrication Shops: General-purpose stock material adaptable to platforms, guards, rails, screens, and project‑specific assemblies.

Contact Us for a Quote Today

Partnering with a supplier that delivers reliable inventory, precise material accuracy, dependable service, and strong technical expertise helps create lasting business relationships and elevates overall customer success. Central Steel Supply Company provides steel products and value-added services that enhance efficiency, reduce delays, and keep projects moving with consistent productivity. Quotes for material availability and processing options are available upon request.

CONTACT

CONTACT