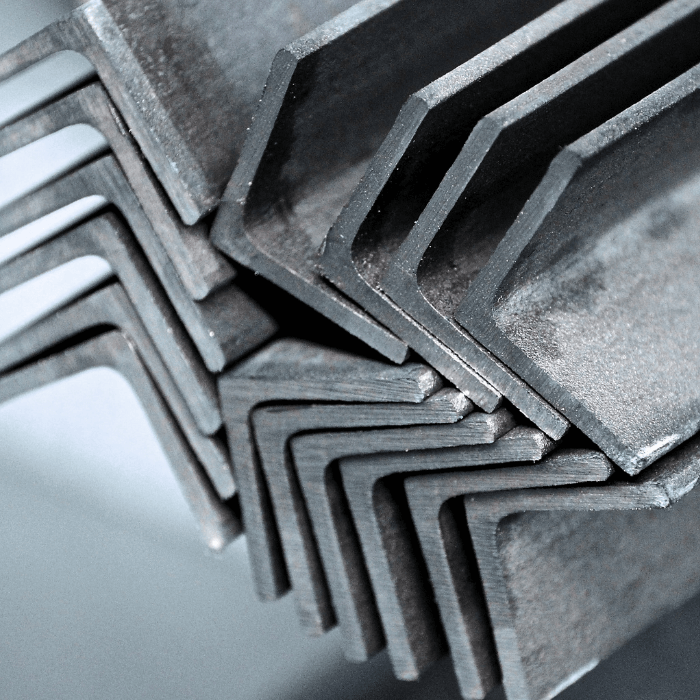

Commonly called angle irons, angle bars, or L-shapes, steel angles are fundamental structural elements used in construction, industrial fabrication, and manufacturing. The L-shaped profile provides rigidity and resistance to bending, making this shape ideal for load-bearing members, bracing, framing, and general reinforcement where strength and stability are essential.

Central Steel Supply Company stocks and processes high-quality, specification-compliant steel angles designed to meet the demands of a wide range of structural and fabrication applications. The following sections outline available angle profiles, in-house processing capabilities, and common uses for these essential structural components.

Dimensions, Grades, and Value-Added Support

Central Steel Supply Company stocks equal and unequal leg steel angles in a wide range of sizes and thicknesses, from ½” × ½” up to 8″ × 8″, with unequal leg angles stocked up to 8″ × 6″. Standard lengths are available up to 40 feet to accommodate diverse project requirements. Additional non-stocked sizes can be coordinated through trusted partner resources when specialized dimensions are needed.

Common Grades for Steel Angles

- A36

- Grade 50 (A572-50)

- A588 (when available)

- CQ / Structural Grades as applicable

Note: Aluminum and Stainless Steel Angles are available upon request through trusted partner resources, allowing Central Steel Supply Company to support broader material requirements while reinforcing strong customer relationships and project efficiency.

Value-added services can be coordinated to supply angles to specified lengths and to provide precise cutting, saw-miter capabilities, and accurately located holes and slots through drilling, punching, and related processing methods. These capabilities support customer fabrication and installation operations by allowing labor and equipment to remain focused on core production and assembly tasks. This approach reduces preparation requirements in both the shop and the job site, minimizes waste, enhances operational efficiency, and strengthens long-term business relationships by contributing to the overall success of each customer’s business.

Processing Services for Steel Angles

Central Steel Supply Company facilitates a range of processing services designed to support customer efficiency, optimize processing operations, and strengthen long-term business relationships. Advanced equipment and trusted partner resources allow material to be prepared to specified dimensions, contributing to the streamlining of customer fabrication and installation workflows.

- AngleMaster: AngleMaster processing supports precise hole and slot punching, shearing to length, and efficient preparation of angle clip profiles, helping customers streamline downstream assembly.

- Saw Cutting: Precision saw cutting, including miter-cut capabilities, enables steel angle material to be supplied in required lengths, supporting accurate alignment and reducing preparation time in both the shop and the job site.

- Drilling and Punching: Drilling and punching services create precisely located holes and slots without the heat effects associated with thermal cutting (laser or plasma), maintaining material integrity, improving consistency, and supporting efficient assembly.

CAD File Integration

CAD files and detailed shop drawings can be imported directly into machine programming, enabling precise control over hole placement, slot geometry, and cutting operations. Central Steel Supply Company also maintains a full CAD department capable of developing or refining CAD drawings as required, enhancing dimensional accuracy and process efficiency. These capabilities support the overall success of each customer’s business by improving process consistency, reducing delays, and helping projects move through fabrication and installation more efficiently.

Industries and Common Applications

L-shaped structural angle profiles provide dependable strength, rigidity, and load-bearing support across a wide range of markets. These angles perform effectively in framing, bracing, and reinforcement applications in the following sectors:

- Commercial Construction and Engineering: Steel angle profiles are widely utilized in commercial projects to establish or reinforce structural frameworks. The design offers consistent lateral support and load-carrying capacity while maintaining dimensional stability under stress.

- Industrial: Industrial operations rely on steel angle profiles for equipment framing, support structures, and general reinforcement where durability and structural reliability are essential.

- Original Equipment Manufacturing (OEM): Within OEM production, steel angle profiles serve as key structural components in machinery, vehicles, and engineered systems requiring stable, load-resistant elements.

- Masonry: Masonry applications use steel angle profiles for lintels, shelf angles, and support elements that carry masonry loads while providing long-term structural stability.

- Landscape Construction: Landscape and site-development projects incorporate steel angle profiles for edging, retaining structures, and various support elements requiring durability and resistance to environmental exposure.

Contact Us for a Quote Today

Partnering with a supplier that delivers reliable inventory, precise material accuracy, dependable service, and strong technical expertise helps create lasting business relationships and elevates overall customer success. Central Steel Supply Company provides steel products and value-added services that enhance efficiency, reduce delays, and keep projects moving with consistent productivity. Quotes for material availability and processing options are available upon request.

CONTACT

CONTACT