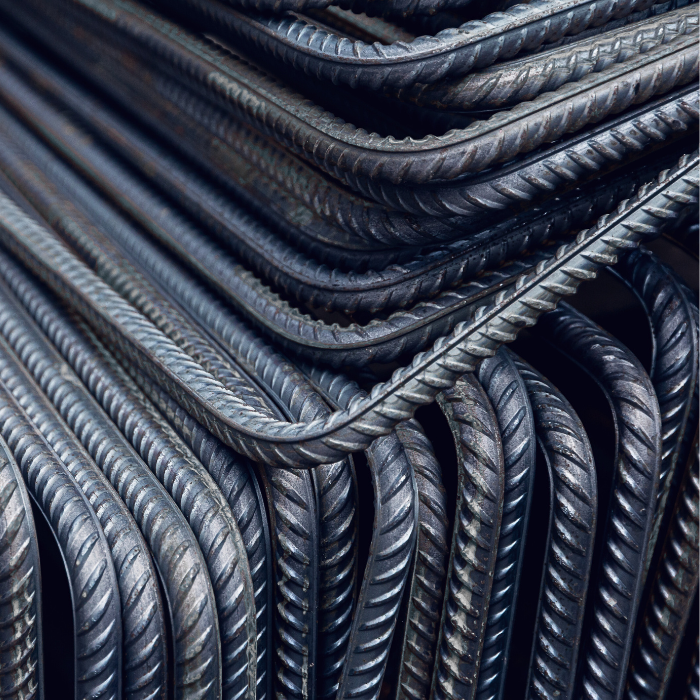

Steel rebar (also referred to as rerod or reinforcing bar) provides reliable tensile reinforcement for concrete structures in commercial, industrial, municipal, and infrastructure construction. The deformed profile enhances mechanical bond strength with concrete, supporting load transfer, crack control, and long-term structural performance.

Central Steel Supply Company stocks specification-compliant reinforcing bar in multiple sizes, grades, finishes, and standard lengths. The following sections outline available dimensions, grades, processing capabilities, and common applications.

Dimensions, Grades, and Value-Added Support

Central Steel Supply Company stocks rebar from #3 (⅜ inch) through #9 (1⅛ inch) in 20-foot and 30-foot standard lengths. Material can be supplied cut-to-length to meet specific project requirements.

Available Finishes

- Bare (Black) Rebar

- Epoxy-Coated Rebar

- Galvanized Rebar*

- *NOTE: Pre-Galvanized rebar is available by special request and may require minimum order quantities. As an alternative to pre-galvanized material, bare rebar can be processed to specification and then coordinated through trusted partner resources for hot-dip galvanizing, supporting projects that require enhanced corrosion resistance.

Common Grades

- Grade 40

- Grade 60

- A706 (Weldable Grade)

Rebar Chairs & Accessories

Central Steel Supply Company also stocks reinforcing bar chairs—commonly referred to as reinforcement supports, slab bolsters, rebar spacers, or concrete chairs—in 1-inch through 5-inch heights and 5-foot lengths. These supports maintain proper bar elevation, alignment, and concrete cover during placement and are commonly used with rebar or wire mesh.

Value-added services can be coordinated to support precise dimensional needs, reduce preparation work on-site, promote installation efficiency, and reinforce strong long-term business relationships by contributing to the overall success of each customer’s business.

Processing Services for Rebar

Central Steel Supply Company facilitates a range of processing services designed to support customer efficiency, optimize production operations, and reinforce strong business relationships. Advanced automated equipment allows reinforcing bar to be prepared to precise shapes and dimensions, contributing to smoother fabrication and installation workflows.

- Saw & Shear Cutting: Saw cutting and shear cutting capabilities allow reinforcing bar to be provided to precise lengths required for project specifications. These cutting methods support clean, consistent ends that promote efficient handling and installation, reduce field preparation, and contribute to predictable reinforcement layout across shop and job-site environments.

- CNC Forming/Bending: A fully automated CNC reinforcement-processing system enables accurate, repeatable production of large batch quantities, supporting high-volume reinforcement schedules, improving installation consistency, and helping maintain project timelines in both shop and field environments. Capabilities include:

- Stirrups

- Standees

- L-bends

- U-shapes

- Circular and polygonal shapes

- Custom reinforcement geometries within machine limitations

- Rebar Detailing, Takeoff & Shop Drawing Support: Rebar detailing, material takeoff, and shop drawing support can be coordinated to assist with accurate quantity development, bar scheduling, and layout clarification. A dedicated CAD capability enables the creation, interpretation, or refinement of reinforcement drawings to promote consistent dimensional accuracy and streamline production sequencing. These services contribute to smoother project coordination and support the overall success of each customer’s business by improving workflow efficiency and reducing the potential for field-level delays.

CAD File Integration

CAD files and detailed placement drawings can be integrated directly into reinforcement programming. A full CAD department is available to develop or refine bar lists and part details, enhancing dimensional accuracy, sequencing, and production efficiency. These services support the overall success of each customer’s business by improving workflow predictability and enabling rapid turnaround on project-critical reinforcement items.

Industries and Common Applications

Steel reinforcing bar is essential to reinforced concrete structures across commercial, industrial, municipal, and infrastructure markets. Applications include foundations, slabs, walls, columns, beams, utility structures, and general concrete assemblies requiring tensile reinforcement.

- Commercial & Residential Construction and Engineering: Foundations, slabs, structural walls, beams, columns, and reinforced concrete assemblies.

- Industrial: Equipment foundations, reinforced pits, slabs, containment structures, and load-bearing concrete components.

- Original Equipment Manufacturing (OEM) – Construction-Related Components: Reinforcement elements incorporated into precast or cast-in-place assemblies used within engineered systems.

- Masonry & Site Work: Reinforced footings, retaining walls, site structures, and formed concrete elements requiring embedded steel.

- Municipal & Infrastructure Work: Reinforcement for bridges, utilities, sidewalks, roadways, culverts, and public-works concrete structures, supporting long-term durability and service performance.

- Landscape Construction: Reinforced concrete features including retaining structures, stairs, edging, and structural landscape components.

Contact Us for a Quote Today

Partnering with a supplier that delivers reliable inventory, precise material accuracy, dependable service, and strong technical expertise helps create lasting business relationships and elevates overall customer success. Central Steel Supply Company provides steel products and value-added services that enhance efficiency, reduce delays, and keep projects moving with consistent productivity. Quotes for material availability and processing options are available upon request.

CONTACT

CONTACT