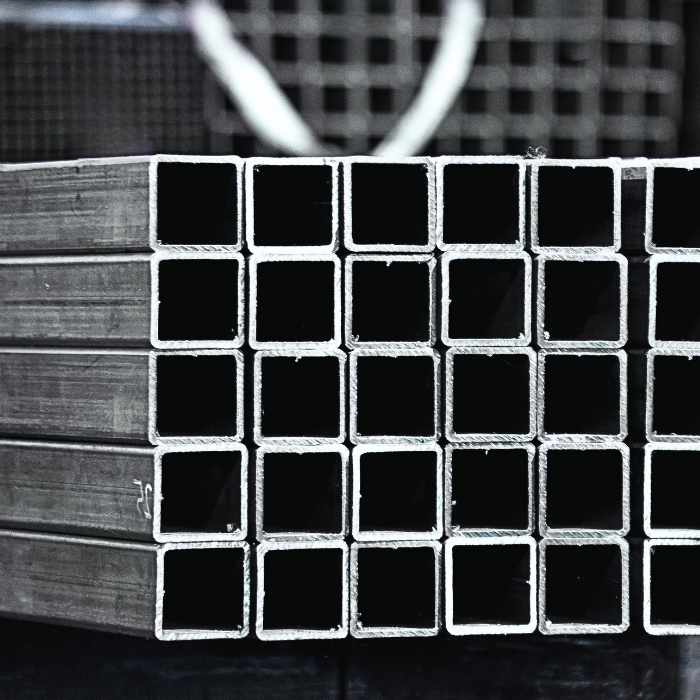

Steel square and rectangular tube provide uniform strength, dimensional stability, and clean structural lines for construction, industrial, and fabrication applications. The closed, multi-axis design offers predictable performance in bending, torsion, and compression, making these profiles suitable for framing, supports, equipment structures, architectural elements, and general structural assemblies.

Central Steel Supply Company stocks specification-compliant square and rectangular tube in a wide range of sizes, wall thicknesses, grades, and standard lengths. The following sections outline available dimensions, grades, processing capabilities, and typical applications.

Dimensions, Grades, and Value-Added Support

Central Steel Supply Company stocks square and rectangular tube in width and height dimensions from ½ inch through 12 inches, with wall thicknesses ranging from .049 inch to .500 inch, supplied in lengths up to 48 feet, depending on size and material. Additional non-stocked dimensions can be coordinated through trusted partner resources when specialized sizing is required.

Common Grades/Finishes for Square & Rectangular Tube

- HR (Hot Rolled)

- HRPO (Hot Rolled Pickled & Oiled)

- CR (Cold Rolled)

- A500 (HSS Structural Tube)

- A513 (Mechanical Tubing)

- 1008 / 1010 / 1020

Note: Aluminum and Stainless Steel Square and Rectangular Tubes are available upon request through trusted partner resources, allowing Central Steel Supply Company to support broader material requirements while reinforcing strong customer relationships and project efficiency.

Value-added services can be coordinated to supply tubing to specified lengths and to provide accurately located holes, slots, cutouts, miters, and coping to support production and installation workflows. These capabilities allow labor and equipment to remain focused on core tasks, reducing preparation in both the shop and the job site, minimizing waste, increasing efficiency, and strengthening long-term business relationships by contributing to the overall success of each customer’s business.

Processing Services for Square & Rectangular Steel Tube

Central Steel Supply Company facilitates processing services designed to support customer efficiency, optimize processing operations, and reinforce strong business relationships. Advanced equipment and trusted partner resources enable square and rectangular tube to be prepared to precise dimensional requirements, contributing to smoother fabrication and installation workflows.

- Saw Cutting: Precision saw cutting—including straight and miter-cut capabilities—allows tubing to be supplied to required lengths, supporting accurate alignment and reducing preparation time in shop and job-site environments.

- Hole, Slot & Cutout Creation: Drilling services allow for accurately located holes, slots, and cutouts in square and rectangular tubing while maintaining material integrity and consistent dimensional quality. Unlike thermal cutting methods such as laser or plasma—which can introduce heat-affected zones, distortion, hardened edges, or taper—drilling produces clean, uniform results that support reliable fit-up, easier downstream fabrication, and superior structural consistency. This approach enhances part accuracy, reduces preparation and cleanup, and supports efficient assembly in both shop and job-site environments.

CAD File Integration

CAD files and detailed shop drawings can be imported directly into machine programming, enabling precise control over hole placement, slot geometry, and cutting operations. Central Steel Supply Company maintains a full CAD department capable of developing or refining CAD drawings when required, enhancing dimensional accuracy and process efficiency. These capabilities support the overall success of each customer’s business by improving process consistency, reducing delays, and helping projects progress more efficiently through fabrication and installation stages.

Industries and Common Applications

Square and rectangular tube provide consistent performance across a wide range of industries. Typical uses include structural frames, supports, architectural features, machinery components, equipment enclosures, and general fabrication requirements.

- Commercial Construction and Engineering: Framing members, supports, architectural features, railing components, and structural assemblies requiring consistent geometry.

- Industrial: Equipment frames, machinery supports, conveyor structures, guards, and enclosures requiring rigidity and clean rectangular profiles.

- Original Equipment Manufacturing (OEM): Machine bases, structural components, equipment frames, and engineered assemblies requiring stable, predictable tube performance.

- Masonry & Site Work: Posts, frames, supports, embedded structural elements, and systems requiring durable rectangular profiles.

- Landscape Construction: Frames, fencing components, gates, supports, and structural elements exposed to environmental conditions.

Contact Us for a Quote Today

Partnering with a supplier that delivers reliable inventory, precise material accuracy, dependable service, and strong technical expertise helps create lasting business relationships and elevates overall customer success. Central Steel Supply Company provides steel products and value-added services that enhance efficiency, reduce delays, and keep projects moving with consistent productivity. Quotes for material availability and processing options are available upon request.

CONTACT

CONTACT